Fluidized Bed Dryer Batch Continuous

Continuous Fluid Bed Dryers

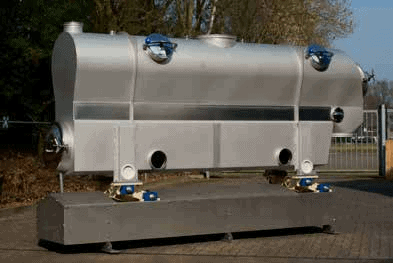

Continuous fluid bed dryer

How does a continuous fluid bed dryer work?

A fluid bed dryer can handle up to 200 t/h and is used for drying of clay, sand, gravel, limestone, etc.

A continuous fluid-bed dryer/cooler is a machine in which a continuous flow of damp, granular material is conveyed over a perforated bed, through which air is blown to bring about fluidization. The material is dried in the first section of the machine and cooled in the second. Drying occurs because of the direct contact between the damp material and the hot air blown through it. The air velocity is adjusted to keep the moving layer of material fluidized. The same mechanism applies to the cooling part of the process, except that the air used is either ambient or conditioned (ie cooled). The drying and cooling sections of the machine form a single conveyor in which the hot and cool air flows are segregated. Conveying of the product is achieved either by means of a low-frequency, high amplitude shaker mechanism.

Fluid bed dryers are specially preferred in mineral drying in combination with after cooling and heat recovery, resulting in better end product quality and very low energy consumptions.

Advantages of continuous fluid-bed dryer system technology

- Low energy consumption compared to other type of dryers

- Accurate control of the residence time, product is dried uniformly

- Gentle on sensitive materials (no friction)

- Low operating costs

- Cooling section integrated in dryer

- Handling of sticky products (from centrifuges or filters)

- Small footprint

- Process flexibility

- Reliable system, less downtime

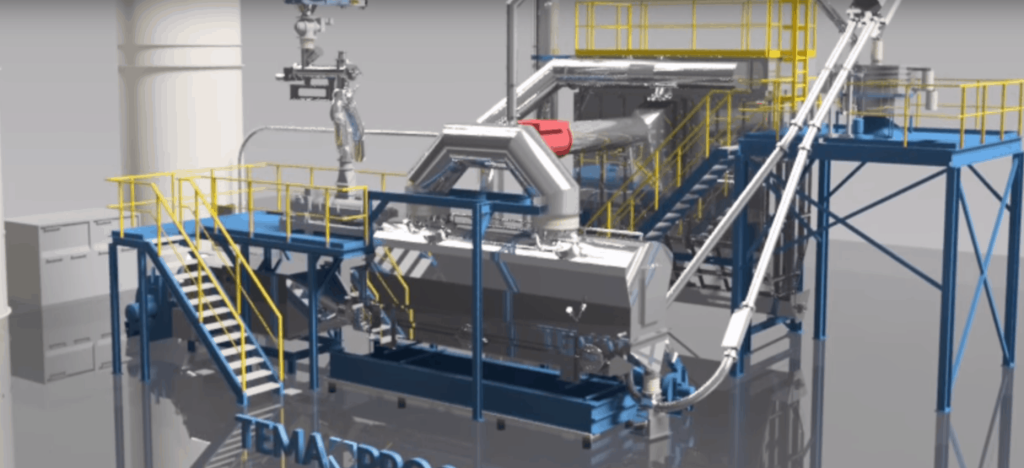

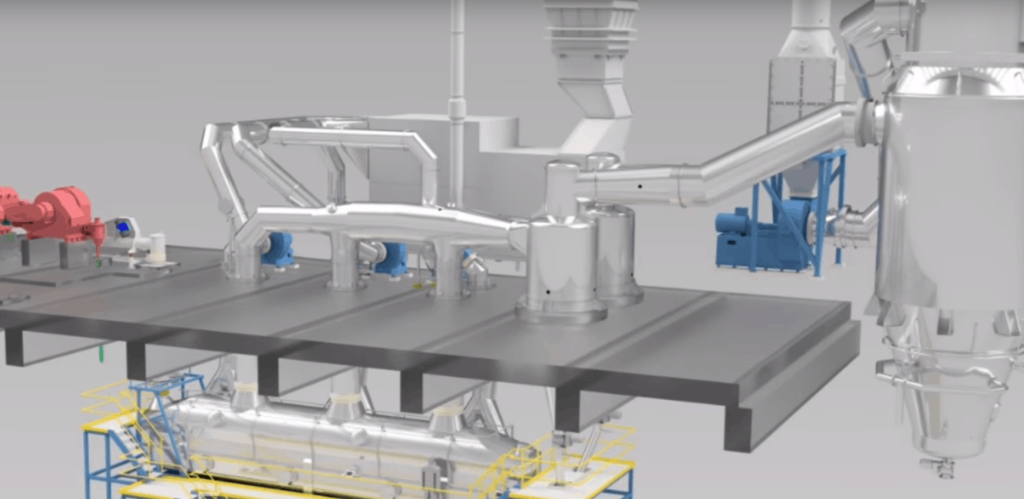

TEMA Process B.V.is a specialised design and manufacturing company for Fluid Bed Systems for drying of minerals, chemicals, food, feed, biomass, etc. The TEMA Fluid Bed can be applied not only for drying, but also for cooling, roasting, torrefaction, puffing, blanching, stripping , spices and herbs sterilisation and pasteurisation and calcining.

TEMA Process B.V. manufactures continuous and batch fluid beds. Batch fluid beds are used when products integrity is required for example in the pharma industry or for small quantities of product. Continuous dryers / coolers can be delivered in static or dynamic (shaking, vibrating) fluid beds. Static fluid bed can be delivered with or without submerged heat exchangers.

Types of Fluid bed dryers

Fluid bed units

A fluid bed is an effective unit to thermally treat powders, crystalline products, pelletized or extruded materials. High heat and mass transfer are obtained as a result of the intimate contact between fluidizing air and product.

Shaking fluid bed

units for continuous operation and suitable for sticky materials with a wide particle size distribution. The shaking motion improves the fluidization and transport of any material within the fluid bed. Drying gas temperature up to 750 °C and product temperatures up to 400 °C are achieved.

Static fluid bed

units in continuous and batch type for more uniform materials that do not tend to agglomerate. It is possible to install submerged heat exchangers in a deep static bed. With submerged heat exchangers energy input is both from the fluidizing air as well as from the heat exchangers reducing the size of the equipment and limiting the exhaust air volume.

Fluid bed dryers & coolers

How does a fluid bed dryer work?

A continuous fluid-bed system is a machine in which a continuous flow of "wet" powder, granular or flakes material is conveyed over a perforated bed. Hot drying air is blown through the holes of a perforated plate. The wet solids are lifted from the bottom and causes the solids to behave as a fluid. The air velocity is adjusted to keep the moving layer of material fluidized.

Conveying of the product is achieved by means of a low-frequency, high amplitude shaker mechanism. The "Shaking" motion plug flow of the Tema fluid bed, allows first-in, first-out drying of products and well-mixed fluidization, which covers the entire spectrum and is able to accurately control the spread of residence time.

Interested?

Are you interested in Fluid bed dryers or can we help you by contacting you over phone or e-mail?

please leave your contact information, one of our specialists will call you back tell you everything you need to know about Fluid bed dryers.

Industries and examples where Fluid Bed Systems can be used for

The TEMA fluid bed systems can be used for all kind of thermal processes like : Drying, cooling, calcining, sterilizing, baking, puffing, roasting, cooking, blanching, steam stripping etc.

The TEMA Fluid Bed systems are used for drying and/or cooling of:

Mineral Industry

Fluid bed dryers are used for processing natural materials, our systems are designed to minimize energy usage, easy to maintain and operate, rigid

construction for challenging environments. The systems are used for drying, cooling, calcining, dedusting, etc

Examples:

- Sand

- quartz sand

- silica sand

- gypsum

- slag sand

- limestone

- kaolin

- potash

- phosphates

- coal

- mineral ores

- etc.

Food and Feed Industry

Fluid bed systems are used for a wide variety of food and feed ingredients, hygienic design as requested in this industry with gentle and even drying to preserve the quality of the materials. Special executions with CIP, GMP design, increased residence time, operating with low oxygen levels are available. The systems are used for drying, cooling, roasting, expanding, removal of solvents, cooking, decontamination, deactivating, etc.

Examples:

- Bread crumbs

- rice

- sugar

- dextrose

- herbs,

- spices

- flaked cereals

- extruded cereals

- milk powder

- lactose

- tomato pulp

- citrus pulp

- fish meal

- fish feed

- animal feed

- return bread

- etc

Chemical Industry

In the chemical industry fluid bed dryers are used to dry all kinds of crystalline materials, powders, extrudates, etc. Special care is taken to select the correct material of construction, minimize effluent to the environment, reduce energy consumption. Systems are used for drying, cooling, removal of solvents, chemical reactions, etc.

Examples:

- Salts,

- sodium chloride

- herbicides

- CMC

- detergents

- ammonium sulphate

- sodium sulphate

- potassium sulphate

- polymers

- PVC

- PVDC

- fertilizers

- plastics

- EPS

- fibres

- coopper

- sulphate

- metal salts

- etc.

Biomass and Waste Industry

In the biomass and waste industry fluid bed dryers are used to dry biomass materials and solid waste materials, sludges and slurries, in order to increase the heating value for biomass and alternative fuels and reduce the volume. Drying takes normally place at lower temperatures between 100 – 200 gr. C by use of waste heat from CHP or boilers.

Examples:

- RDF

- poultry

- litter

- cow dung

- dewatered slurry

- digester sludge

- fermenter waste

- lemon peel

- orange peel

- manure

- paper sludge

- wood

- biomass

- etc.

Want more info? download our technical sheet

Are you interested in Fluid bed dryers?

We offer our technical sheets for free in different languages.

Download our technical sheets on our download page.

Download sheets

Source: https://temaprocess.com/continous-fluid-bed-dryers/

0 Response to "Fluidized Bed Dryer Batch Continuous"

Post a Comment